Laser cutting:

• Laser Mazak Optiplex DDL

• Laser Mazak Optiplex Fiber3

• Laser Prima Industrie Platino CV5000

Maximum dimensions 4000x2000

Thicknesses cut: Carbon steel from 0.5 to 20mm, Stainless steel from 1 to 15mm

oxy-fuel cutting:

• Pantograph Oxyfuel Soitaab

Maximum dimensions: 8.000x2.500

Thicknesses cut: Carbon Steel from 10 to 60mm

Types of materials processed: Carbon Steel S235JR, S275JR, S355J2, Corten Stainless Steel AI304, AI316 (finishes F1, 2B, Scotch-brite, Satin, BA), Anti-wear Steel (eg. Hardox 400/450), Steel High yield strength (eg. Weldox, S690), Aluminium.

• Laser Adige LT8

• Laser TTM FL300

Minimum bar load length 3500mm

Maximum bar load length 8000mm

Processing commercial profiles (Round, Rectangle, Square, Angular, UPN)

Working diameter from 20 to 300mm

Maximum load of 40kg/mt

Types of materials processed: Carbon Steel S235JR, S275JR, S355J2 Stainless Steel AI304, AI316, Aluminium.

• LVD ULTI-FORM 135/30

• LVD PPBE 400/50

• CBC tipo HS 400/41

• Bystronic Beyeler PR150x3100IPc

Maximum length of bended part up to 4 mt

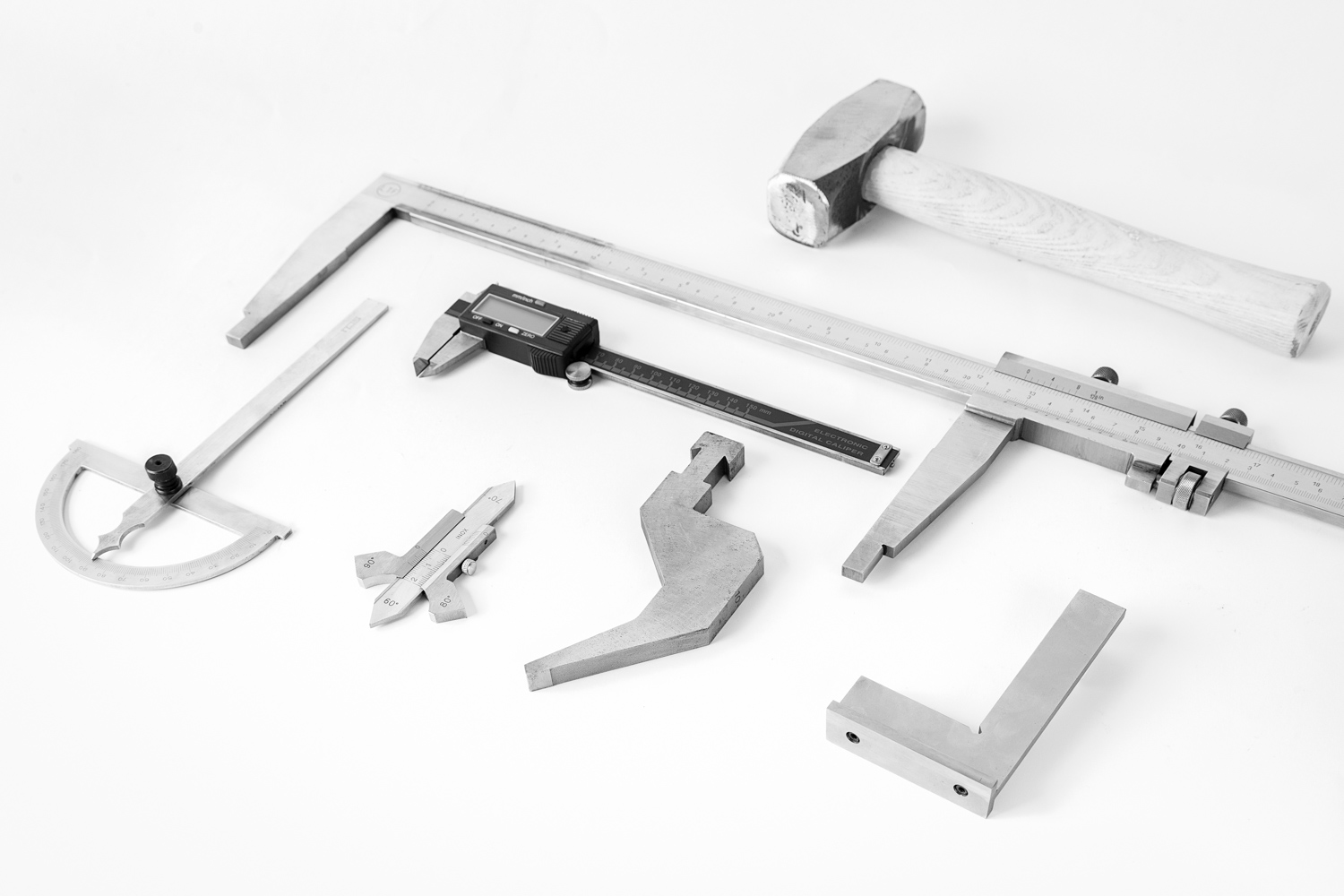

Our Technical Department is able to bend metal sheets as per customers drawings.

The many years of experience gained in the sector allows LamieraPiù to suggest ideal bending solutions suitable for any production requirement for medium/light metalwork.

• 5 Welding stations (Welding machines - Fronius, Kemppi, ElettroCF);

• 2 Robot Welding Machines;

• Hydraulic bending machine MG 4 rollers model 208;

• Radial drill;

• Drill press;

• Manual chamfering machine.

The Metal work department is able to provide a service of small/medium metalwork production: MIG wire welding for carbon steel, upon request we also provide certified welding; TIG welding of Carbon steel; Calendering; Drilling; Threading; Countersinking; Riveting; Chamfering. As required by EN 1090 regulations, we have qualified personnel with welding certifications.

Upon request LamieraPiù also provides ancillary services, turning to its network of qualified suppliers for processes such as:

• Punching, Turning, Boring, Deep drawing, Moulding and other types of Mechanical Machining;

• Surface Treatments such as: Painting, Galvanizing, Chrome plating, Burnishing, Phosphating, Polishing, Anodizing, Cataphoresis treatment;

• Welding of stainless steel;

• Welding for Medium/Heavy metalwork;

• Assembly work.